The Airlander 10 production design is the product of months of hard work from our engineering team. You can read all about the main design changes here but this article is focused specifically on the improvements to the aerodynamic profile of Airlander 10.

A quick overview from our Chief Technical Officer, Mike Durham, before we dive into the detail:

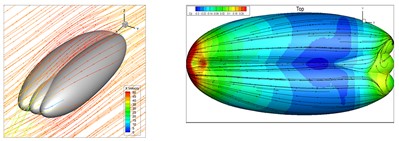

“We have significantly reduced the aerodynamic drag when compared to the prototype, reducing fuel burn and therefore operating costs and environmental impact. This drag reduction has come from modification to the hull shape. We have worked closely with the Mercedes-AMG Petronas F1 Team Applied Science Division in their wind tunnel at Silverstone. We tested a 1.3m long physical model of Airlander that enables us to add or remove ‘features’, so we could understand what works and what doesn’t. Alongside this physical testing, we have invested heavily in computer simulation of the aircraft via computational fluid dynamics (CFD) to help us scale the information from the wind tunnel up to the full-size production aircraft and to correlate the wind tunnel data to the flight test data from the full size prototype.”

Aerodynamics explained

The shape of any vehicle must be developed so that it can be propelled through the air (or water) with minimum resistance. A poor shape will result in high drag forces and the need for more powerful engines with the associated high fuel consumption, adverse environmental impact and increased operating costs.

How we analysed Airlander 10’s aerodynamic flow characteristics

The HAV aerodynamics team used a combination of CFD and wind tunnel testing.

CFD involves the use of high-performance computers and complex mathematical codes to calculate and analyse the airflow over the computer-generated models for the main aircraft components. By using CFD we were able to analyse how well the air flows over the shape of Airlander 10.

For the wind tunnel testing we worked closely with the Mercedes-AMG Petronas F1 Team Applied Science Division to carry out our testing in their wind tunnel.